Research // Energy converters (Magnets)

SmartPro – Key to Smart Products!

New magnetic materials and technologies for electrical energy converters are of outstanding importance – for resource-saving mobility, renewable energy, and industrial automation (Industry 4.0).

Within the projects in the field of energy converters, everything revolves around magnets, which are needed in electric motors, generators, and other systems. The aims of the projects are to produce magnets using smaller quantities of critical raw materials such as rare-earth metals, improve their durability, and improve the way magnets work in their application systems. These steps lay the foundations for energy-efficient products.

To make this happen, the SmartPro researchers work with companies along the entire supply chain. These issues are pursued intensively in the projects MagNetz (2017-2020) and Smart-MAG (2021-2024), two impulse projects of the SmartPro partnership.

Smart-MAG

// Project duration: 01.01.2021 to 31.12.2024

Project management

Prof. Dr. Dagmar Goll

Materials Research Institute Aalen

Phone: +49 (0) 7361 576-1601

dagmar.goll@hs-aalen.de

Project partners

Aalen University

- Dr. Timo Bernthaler, Materials Research Institute Aalen

- Prof. Dr. Gerhard Schneider, Materials Research Institute Aalen

- Prof. Dr. Heinrich Steinhart, Institut für Antriebstechnik Aalen

- Prof. Dr. Markus Glaser, Zentrum für Zuverlässige Mechatronische Systeme

Companies

- AMK Arnold Müller GmbH & Co. KG Antriebs- und Steuerungstechnik

- ANDREAS STIHL AG & Co. KG

- Antriebstechnik GmbH FAURNDAU

- Carl Zeiss IMT

- Carl Zeiss Microscopy GmbH

- Daimler / Mercedes AG

- Dietz-motoren GmbH & Co. KG

- Dürr Technik GmbH & Co. KG

- Kessler & Co. GmbH & Co. KG

- MS-Schramberg GmbH & Co. KG

- Robert Bosch GmbH

- SEG Automotive Germany GmbH

- Vacuumschmelze GmbH & Co. KG

- Wieland-Werke AG

Other research institutions

- Hochschule Pforzheim – Institut für strategische Technologie- und Edelmetalle (STI)

- Karlsruher Institut für Technologie (KIT) – Institut für Nanotechnologie (INT)

- Max-Planck-Institut für Intelligente Systeme

- Universität Stuttgart – Institut für Elektrische Energiewandlung (IEW)

Transfer players

e-mobil BW GmbH

Smart-MAG

Tailored magnets of assured quality for efficiency optimized electric motors

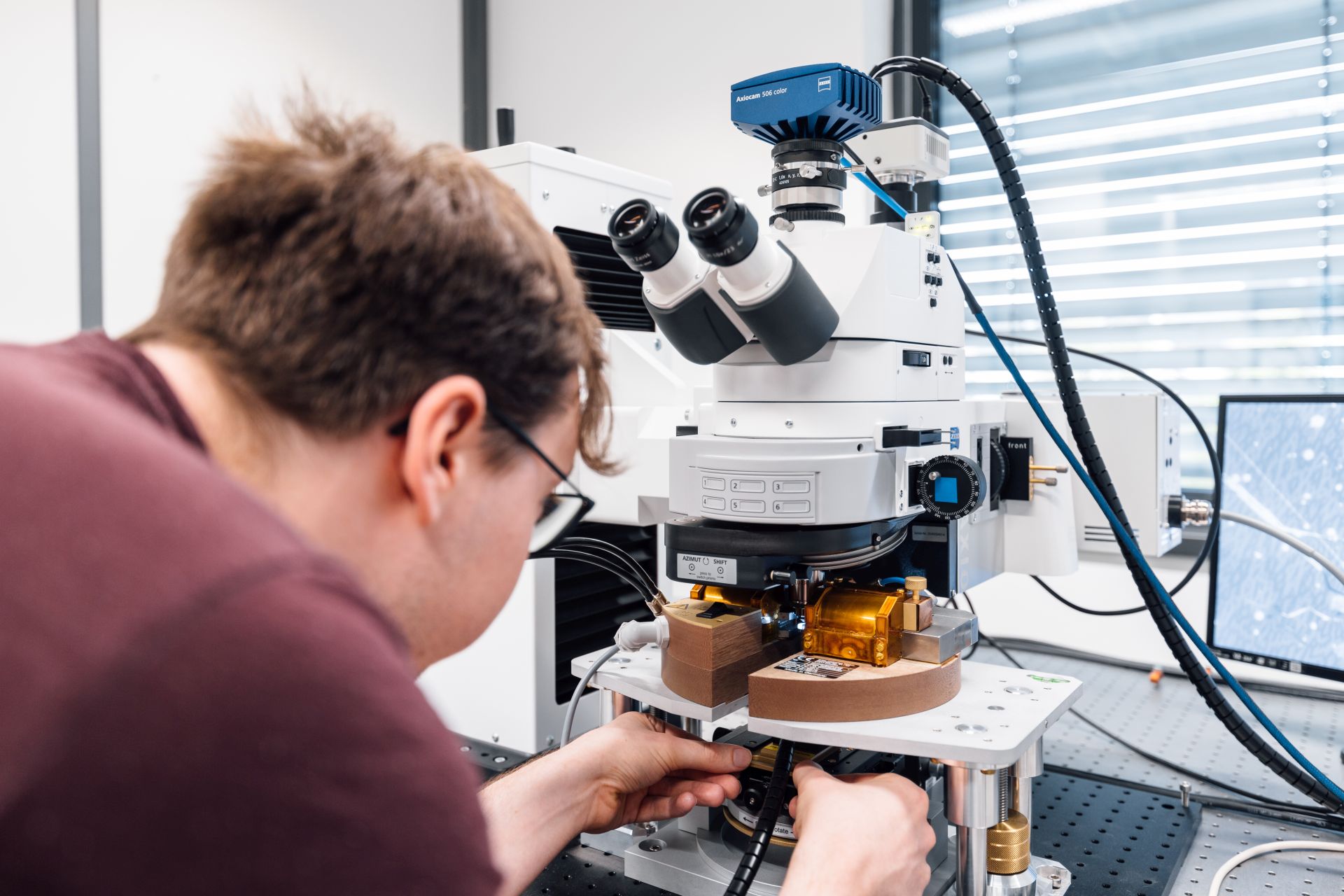

The ongoing electrification of many sectors and the expansion of wind power require energy converter machines that are lightweight and compact yet high performance and energy efficient. In this context, smart magnetic materials and intelligent technologies for their characterization as well as predictive operation strategies are indispensable to avoid demagnetization in electric machines. These aspects are examined in the impulse project Smart-MAG.

The area of “magnetic materials” is focused on designing optimized materials for each specific application – considering performance, use of resources, cost-effectiveness, and resistance to aging. Customized and quality-assured magnets reduce the need for critical raw materials (for example, rare earth metals), thus conserving valuable resources.

In addition, efficiency-optimized electric motors are developed with the consideration of both economic and ecological conditions. This strategy paves the way to increase the efficiency and service life of magnets and thus also the sustainability of devices and machines. The evaluation and assurance of quality – also in the operating state – play important roles here. For this purpose, machine learning-based methods are used.

In addition, new approaches on how losses can be minimized are explored. This can be achieved for example by reliably determining and then specifically reducing individual losses. The development of a model for monitoring the condition of machines is also intended to prevent life-shortening demagnetization of the installed magnets.

MagNetz

Smart magnetic materials and tools for their quality assessment for lightweight, compact, and efficient electric motors

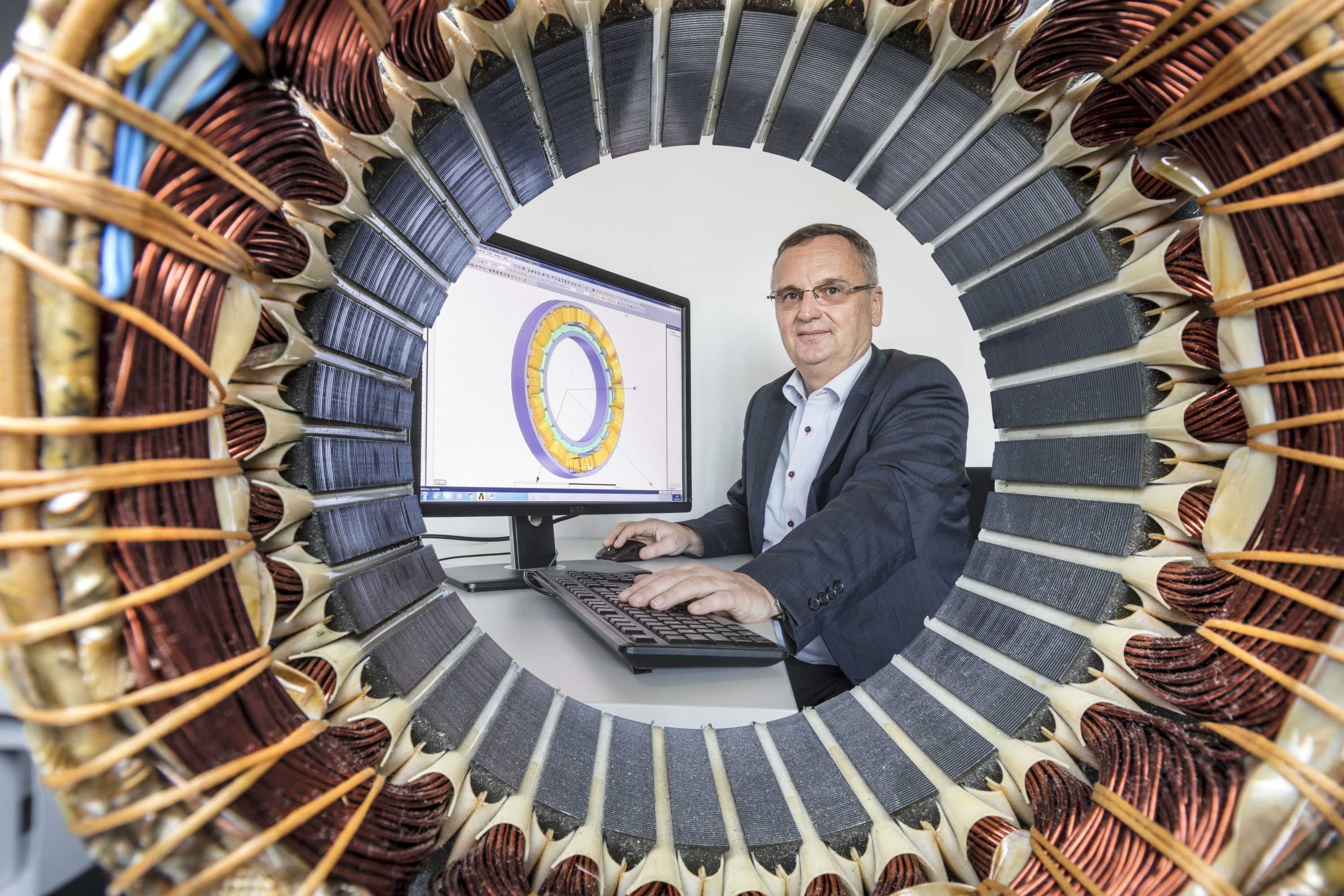

Magnets are omnipresent: in electric motors, generators, and actuators in stationary as well as mobile systems and battery-powered devices. Magnet technologies in these electrical energy converters enable the efficient use of energy for smart mobility, wind power, and power tools as well as Industry 4.0-compliant factory automation.

The magnetic materials currently used are very cost-intensive due to the use of rare-earth metals. They often also exhibit increased magnetic losses. New magnetic materials whose properties have been tailored to the respective system requirements are therefore key to market-attractive, energy-efficient, and resource-saving products. To ensure the quality of the smart magnetic materials developed, innovative tools were devised to evaluate not only the functional properties like material quality but also the process quality and aging resistance.

In addition, the prerequisites for a precisely-fitting design of sustainable energy converter machines were improved. Individual losses were balanced and condition monitoring was used to protect the installed magnets. This was achieved based on a newly-developed simulation model validated on sample motors with optimized materials.

MagNetz

// Project duration: 01.01.2017 to 31.12.2020

Project management

Prof. Dr. Dagmar Goll

Materials Research Institute Aalen

Phone: +49 (0) 7361 576-1601

dagmar.goll@hs-aalen.de

Project partners

Aalen University

- Dr. Timo Bernthaler, Materials Research Institute Aalen

- Prof. Dr. Arif Kazi, Fakultät Optik und Mechatronik

- Prof. Dr. Gerhard Schneider, Materials Research Institute Aalen

- Prof. Dr. Heinrich Steinhart, Institut für Antriebstechnik Aalen

- Prof. Dr. Markus Glaser, Zentrum für Zuverlässige Mechatronische Systeme

Companies

- AMK Arnold Müller GmbH & Co. KG Antriebs- und Steuertechnik

- ANDREAS STIHL AG & Co. KG

- Antriebstechnik GmbH FAURNDAU

- Carl Zeiss Microscopy GmbH

- Daimler AG

- Dürr Technik GmbH & Co. KG

- Georgii Kobold GmbH & Co. KG

- GTS Generator. Technik. Systeme. GmbH & Co. KG

- Robert Bosch GmbH

- Vacuumschmelze GmbH & Co. KG

Other research institutions

- Fraunhofer–Institut für Werkstoffmechanik (IWM)

- Karlsruher Institut für Technologie (KIT) – Institut für Nanotechnologie (INT)

- Max-Planck-Institut für intelligente Systeme

Transfer players

- e-mobil BW GmbH

Follow us!

Stay up to date about the

SmartPro network on LinkedIn!

Explorative projects

In the explorative projects within the application field of energy converters, the development and production of magnets were intensively pursued. These projects investigated for example the fabrication of magnets via additive manufacturing and using methods of artificial intelligence (machine learning) for quality assurance.

ProxiMat // Process innovations for additive manufacturing of oxidation-sensitive materials

01.08.2020 to 31.10.2021

The development of cost-effective and resource-saving permanent magnets is one of the foundations for innovative energy converters for future electromobility. The use of new manufacturing technologies such as additive manufacturing (for example 3D printing) opens up innovative approaches for the production of energy- and resource-efficient energy converters for a variety of application areas. The exploratory project ProxiMat focused on technological enhancements to improve the properties of permanent magnets.

In an innovative approach for additive manufacturing of neodymium-iron-boron magnets, optimized materials with the smallest possible grain size and ultra-fine directed microstructure were developed on a laboratory scale (and characteristic parameters experimentally determined). In direct connection with this, alternative and more economical processes for production of the employed starting alloys were also investigated.

Beyond this, an application of laser-based additive manufacturing of permanent magnet components made of carbon-iron-neodymium was tested, as it is currently only available for cast elements. Likewise, the emerging possibilities of manufacturing technology for the production of anisotropic components were investigated.

- Project management

Prof. Dr. Dagmar Goll, Materials Research Institute Aalen

- Project partner

Dr. Timo Bernthaler, Materials Research Institute Aalen

Prof. Dr. Gerhard Schneider, Materials Research Institute Aalen

DiMa // Digitization potentials of materials research in SmartPro

01.10.2019 to 30.09.2020

In the explorative project DiMa, interdisciplinary approaches were used to generate new research content for the tailored further development of machine learning (ML) methods. For this, the methodological expertise of ML experts was combined with expertise in the other research areas of SmartPro.

Four subprojects were proceeded − each assigned to one of the impulse projects and served as a starting point for the development of the cross-sectional impulse project BEYOND with a focus on ML.

The subproject MagTwin (assigned to the impulse project MagNetz to energy converters) focused on the development of a digital twin of a permanent magnet test bench. Most importantly, the aging processes of permanent magnets were simulated.

- Project management

Prof. Dr. Ricardo Büttner, Business Informatics

- Project partner

Prof. Dr.-Ing. Sebastian Feldmann, Digitale Systemintegration im Maschinenbau

Prof. Dr. Dagmar Goll, Materials Research Institute Aalen

SmartCycle // Smart Recycling Solutions for Future Technologies

01.05.2023 – 31.07.2025

The recycling and circular economy of materials in the areas of energy converters, energy storage systems, and lightweight construction – the three fields of application addressed by SmartPro research – are vital for sustainable resource management. By implementing efficient recycling processes and embracing circular economy principles, valuable materials can be recovered from waste, reducing the need for raw material extraction and minimizing environmental impact. The aim of the explorative SmartPro project SmartCycle is to explore new recycling strategies and further develop methods to perform these practices. This project will shed light on innovative recycling methods and thus contribute to conserving resources, promoting energy efficiency, and fostering a more sustainable and environmentally-conscious approach to the production and use of magnets, batteries, and lightweight construction materials.

To achieve these goals, SmartCycle is divided into five sub-projects, aligned with the three application fields addressed by SmartPro (energy converters, energy storage systems, and lightweight construction) as well as the interdisciplinary technology of machine learning.

- Project management

Prof. Dr. Iman Taha, Sustainable Materials in Plastics Technology

The RecyMAG sub-project focuses on developing innovative recycling processes for magnets, which are a key material in electromobility. Innovative recycling processes for magnets would allow rare-earth metals such as neodymium to be extracted, purified, and reintroduced into the production cycle. Therefore, when electric motors reach the end of their lifecycle, the magnetic components can be reused. This reduces the reliance on new materials and minimizes the environmental impact of manufacturing electromobility products, contributing to the overall goal of reducing the environmental footprint of electric vehicles.

- Sub-project management

Prof. Dr. Dagmar Goll, Materials Research Institute Aalen

SmartPro // FH-Impuls:

Strong universities of applied sciences - impulses for the region

With SmartPro, Aalen University of Applied Sciences has positioned itself in the top group of universities of applied sciences nationwide. SmartPro is one of ten partnerships funded through the “FH-Impuls” program of the Federal Ministry of Education and Research with around 10 million euros from 2017 until 2025. Core objectives are the sustainable expansion of the regional transfer and cooperation network as well as strengthening the research profile and innovative power. SmartPro contributes to the advancement of climate protection and digitalization, two key social challenges.